Implementation Of Lean Six Sigma

Here's an overview:

- Introduction to Six Sigma in Pharmaceutical Operations

- Benefits of Implementing Six Sigma in Pharmaceutical Operations

- Key Principles of Six Sigma in the Pharmaceutical Industry

- Steps to Implement Six Sigma in Pharmaceutical Operations

- Challenges Faced in Implementing Six Sigma in Pharmaceutical Operations

- Case Studies of Successful Six Sigma Implementation in Pharmaceutical Companies

- Training and Certification for Six Sigma in the Pharmaceutical Industry

- Measuring the Success of Six Sigma Implementation in Pharmaceutical Operations

- Continuous Improvement and Sustainability in Six Sigma for Pharmaceutical Operations

- Future Trends and Innovations in Six Sigma for Pharmaceutical Operations

Introduction to Six Sigma in Pharmaceutical Operations:

Six Sigma is a data-driven methodology widely used in various industries, including pharmaceutical operations, to improve processes, reduce errors, and enhance overall efficiency. In the pharmaceutical sector, where precision and quality are paramount, Six Sigma plays a crucial role in driving continuous improvement and ensuring compliance with regulatory standards.

- Six Sigma focuses on identifying and eliminating defects in processes by emphasizing measurement, analysis, and improvement.

- By implementing Six Sigma principles, pharmaceutical companies can streamline production, enhance product quality, and ultimately increase customer satisfaction.

- Pharmaceutical operations involve complex processes that can benefit significantly from the structured approach provided by Six Sigma.

- The DMAIC (Define, Measure, Analyze, Improve, Control) methodology of Six Sigma guides organizations in systematically tackling process issues and achieving sustainable results.

- Through Six Sigma projects, pharmaceutical companies can optimize critical processes such as drug development, manufacturing, packaging, and distribution.

Overall, understanding and implementing Six Sigma in pharmaceutical operations can lead to cost savings, waste reduction, and improved product reliability, ultimately contributing to a more efficient and competitive pharmaceutical industry.

Benefits of Implementing Six Sigma in Pharmaceutical Operations:

- Six Sigma implementation in pharmaceutical operations offers precise tools and methodologies to streamline processes and enhance overall efficiency.

- Reduction in defects and errors leads to improved product quality and safety within the pharmaceutical industry.

- Enhanced process standardization through Six Sigma ensures consistent and reliable outcomes, crucial for pharmaceutical operations.

- By focusing on data-driven decision-making, Six Sigma facilitates better resource utilization and cost reduction in pharmaceutical processes.

- Increased customer satisfaction is a key benefit of implementing Six Sigma, as it aligns operations with quality standards and expectations.

- Six Sigma helps in identifying performance gaps and areas for improvement, leading to continuous enhancement of pharmaceutical operations.

- Compliance with regulatory requirements is enhanced through Six Sigma practices, ensuring adherence to strict industry standards.

- Risk mitigation is improved with Six Sigma as it enables proactive problem-solving and prevention of potential issues within pharmaceutical operations.

- Implementation of Six Sigma fosters a culture of continuous improvement and learning, essential for long-term success in pharmaceutical operations.

- Overall, the systematic approach of Six Sigma results in improved operational efficiency, reduced waste, and increased profitability for pharmaceutical companies.

Key Principles of Six Sigma in the Pharmaceutical Industry:

- Six Sigma emphasizes data-driven decision-making to improve processes and reduce defects in the pharmaceutical industry.

- The DMAIC (Define, Measure, Analyze, Improve, Control) methodology is commonly used in Six Sigma projects to achieve operational excellence.

- Six Sigma in the pharmaceutical industry focuses on enhancing product quality, increasing efficiency, and ensuring patient safety.

- Process optimization and standardization are key components of implementing Six Sigma principles in pharmaceutical operations.

- Continuous improvement is at the core of Six Sigma, fostering a culture of ongoing learning and development within pharmaceutical organizations.

- Cross-functional teamwork and collaboration are essential for successful Six Sigma implementation in the pharmaceutical sector.

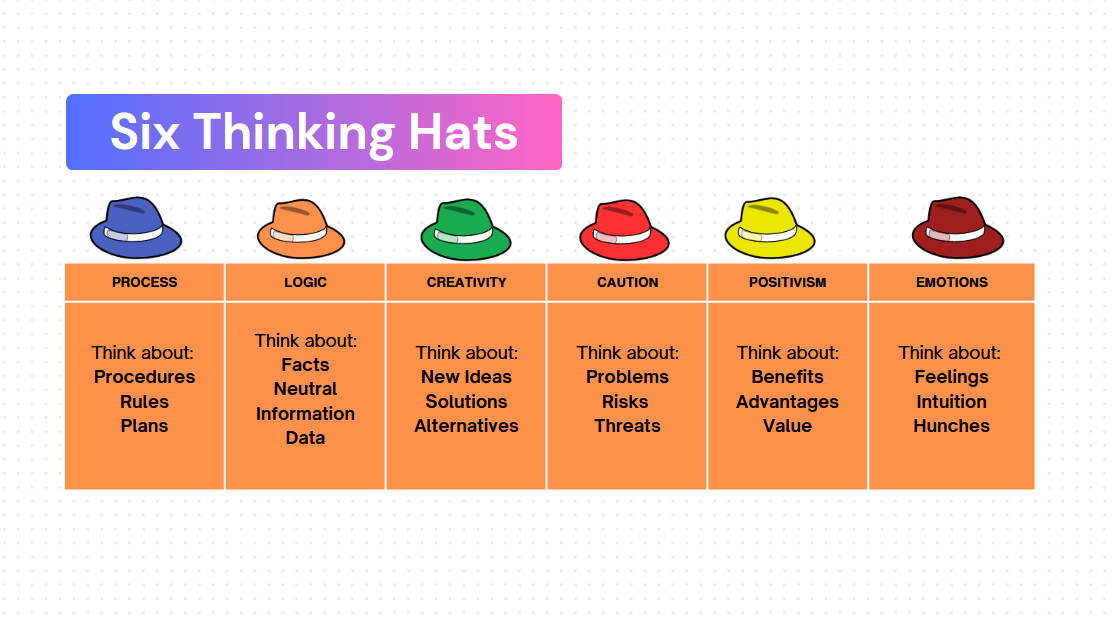

- Six Sigma tools and techniques such as control charts, root cause analysis, and statistical analyses are integral to driving process improvements in pharmaceutical operations.

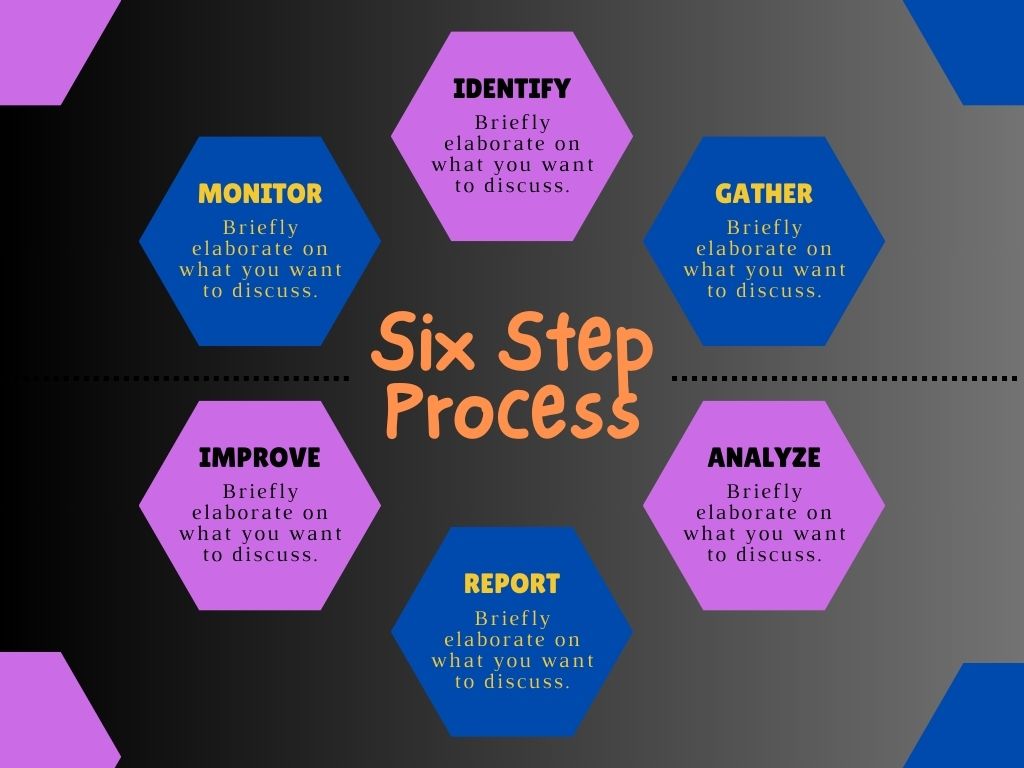

Steps to Implement Six Sigma in Pharmaceutical Operations:

- Identify Key Processes: Begin by identifying the key processes within the pharmaceutical operations that directly impact quality, efficiency, and cost. This step involves analyzing current workflows, identifying potential areas for improvement, and prioritizing processes that will benefit most from Six Sigma implementation.

- Establish Clear Goals: Set specific, measurable, achievable, relevant, and time-bound (SMART) goals for the Six Sigma project in pharmaceutical operations. Clearly defined goals help align efforts, track progress, and ensure that the implementation stays on track towards achieving desired outcomes.

- Build a Cross-Functional Team: Assemble a cross-functional team comprising members from different departments within the pharmaceutical operations. This team should include individuals with varying expertise and perspectives to ensure comprehensive problem-solving and effective implementation of Six Sigma methodologies.

- Provide Training: Offer comprehensive training on Six Sigma principles, tools, and methodologies to all team members involved in the pharmaceutical operations project. Training ensures a common understanding of Six Sigma concepts and equips team members with the skills needed to drive successful implementation.

- Measure Current Performance: Utilize data and metrics to assess the current performance of the identified processes within pharmaceutical operations. Establish baseline measurements to quantify key performance indicators (KPIs) and identify areas where improvements are needed to meet Six Sigma standards.

- Implement Improvement Strategies: Utilize Six Sigma tools such as DMAIC (Define, Measure, Analyze, Improve, Control) to systematically analyze processes, identify root causes of inefficiencies, and implement data-driven solutions to improve quality and operational efficiency within pharmaceutical operations.

- Monitor and Control: Continuously monitor the progress of the Six Sigma implementation in pharmaceutical operations and use control mechanisms to sustain improvements. Regularly review performance metrics, conduct audits, and address any deviations from the established processes to ensure long-term success.

By following these steps diligently, pharmaceutical operations can effectively implement Six Sigma methodologies to drive continuous improvement, enhance quality, and optimize operational performance.

Challenges Faced in Implementing Six Sigma in Pharmaceutical Operations:

- Implementing Six Sigma in pharmaceutical operations comes with its fair share of challenges, stemming from the highly regulated nature of the industry and the critical need for precision and accuracy in every stage of the process.

- Resistance to change among employees can be a significant hurdle when introducing Six Sigma principles. Some staff members may be hesitant to adopt new methodologies or may fear that the new processes will disrupt their routine.

- The complex and interconnected nature of pharmaceutical operations can also pose a challenge. Implementing Six Sigma requires a thorough understanding of the entire workflow and how each part impacts the overall process.

- Data availability and quality can be another obstacle. Pharmaceutical operations generate vast amounts of data, but ensuring its accuracy and reliability is crucial for the success of any Six Sigma initiative.

- Regulatory requirements add an additional layer of complexity. Pharmaceutical companies must adhere to stringent regulations, and implementing Six Sigma without compromising compliance can be a delicate balancing act.

- Another challenge is the need for specialized expertise. Six Sigma principles require specific skills and knowledge, and training employees to become proficient in these methodologies can be time-consuming and resource-intensive.

- Finally, measuring the success of Six Sigma initiatives in pharmaceutical operations can be challenging. Determining the impact of process improvements on key performance indicators requires robust measurement systems and data analysis capabilities.

Case Studies of Successful Six Sigma Implementation in Pharmaceutical Companies:

- Pfizer: Pfizer, a leading pharmaceutical company, implemented Six Sigma methodologies to improve its manufacturing processes. By applying Six Sigma tools such as process mapping, root cause analysis, and statistical analysis, Pfizer was able to identify and eliminate defects in its production line. As a result, Pfizer saw a significant increase in product quality, a reduction in production costs, and improved customer satisfaction.

- Novartis: Novartis, another major player in the pharmaceutical industry, utilized Six Sigma to streamline its supply chain operations. Through the implementation of Six Sigma principles, Novartis was able to reduce lead times, optimize inventory levels, and enhance overall efficiency. The company reported a marked improvement in on-time delivery performance and a decrease in production delays.

- Merck: Merck, a global pharmaceutical company, applied Six Sigma methodologies to enhance its research and development processes. By implementing Six Sigma tools such as DMAIC (Define, Measure, Analyze, Improve, Control), Merck was able to identify inefficiencies in its R&D pipeline and make data-driven improvements. This led to accelerated drug development timelines, cost savings, and an increase in innovation.

These case studies highlight the effectiveness of Six Sigma in driving operational excellence and improving key performance metrics within pharmaceutical companies.

Training and Certification for Six Sigma in the Pharmaceutical Industry:

- Six Sigma Green Belt Training: Individuals in the pharmaceutical industry can benefit from Six Sigma Green Belt training, which equips them with a foundational understanding of Six Sigma principles and methodologies. This training covers topics such as process improvement, data analysis, and statistical tools essential for quality enhancement in pharmaceutical operations.

- Six Sigma Black Belt Certification: For professionals looking to take on leadership roles in process improvement projects within the pharmaceutical sector, obtaining a Six Sigma Black Belt certification is crucial. This advanced training provides in-depth knowledge of statistical analysis, project management, and advanced Six Sigma tools to drive significant operational improvements.

- Customized Training Programs: Pharmaceutical companies often opt for customized Six Sigma training programs tailored to their specific operational needs and challenges. These programs can focus on areas such as reducing cycle times, improving manufacturing processes, or enhancing supply chain efficiency, ensuring that the training directly addresses the company's improvement goals.

- On-the-Job Implementation: In addition to formal training programs, hands-on experience in applying Six Sigma methodologies in real-world pharmaceutical operations is essential for honing skills and driving sustainable improvements. Companies should provide opportunities for employees to work on Six Sigma projects and gain practical experience in problem-solving and process optimization.

- Continuous Learning and Development: Continuous learning and skill development are essential for maintaining Six Sigma standards in the pharmaceutical industry. Employees should engage in ongoing training, attend refresher courses, and stay updated on industry trends to ensure that their Six Sigma knowledge remains current and relevant to drive continuous improvement in pharmaceutical operations.

Measuring the Success of Six Sigma Implementation in Pharmaceutical Operations:

- Key Performance Indicators (KPIs) are essential in measuring the success of Six Sigma implementation in pharmaceutical operations.

- Metrics such as defect rate reduction, cycle time improvement, cost savings, and customer satisfaction levels are commonly used to evaluate the effectiveness of Six Sigma projects.

- Tracking and analyzing KPI data before and after implementing Six Sigma initiatives helps determine the impact on operational efficiency and quality.

- Utilizing tools like Control Charts, Process Capability Analysis, and Root Cause Analysis assist in monitoring and analyzing KPI trends accurately.

- Conducting regular reviews and assessments of KPIs with stakeholders and project teams ensures alignment with organizational goals.

- Comparing KPI results with industry benchmarks and best practices provides insights into the competitive performance of pharmaceutical operations.

- Continuous improvement methodologies within Six Sigma projects allow for ongoing monitoring and adjustment of KPI targets for sustained success.

- Involving employees at all levels in KPI measurement and analysis fosters a culture of accountability and performance-driven mindset within the organization.

Continuous Improvement and Sustainability in Six Sigma for Pharmaceutical Operations:

- Implementing Six Sigma in pharmaceutical operations requires a continuous improvement mindset to achieve sustainable results.

- Continuous improvement involves regularly reassessing processes to identify areas for enhancement.

- It is essential to establish a culture of continuous improvement within the organization to ensure long-term success.

- Engaging employees at all levels in the Six Sigma process can foster a sense of ownership and commitment to improvement initiatives.

- Sustainability in Six Sigma for pharmaceutical operations necessitates ongoing training and development to maintain skill levels and knowledge.

- Regular monitoring and evaluation of key performance indicators are vital to track progress and identify opportunities for further improvement.

- Embracing the principles of sustainability ensures that the benefits of Six Sigma initiatives are enduring and impactful.

- Pharmaceutical companies should integrate sustainability practices into their Six Sigma strategies to optimize operational efficiency and reduce waste.

- By focusing on continuous improvement and sustainability in Six Sigma, pharmaceutical operations can enhance quality, increase productivity, and drive overall success.

Future Trends and Innovations in Six Sigma for Pharmaceutical Operations:

- The pharmaceutical industry is constantly evolving, and so are the trends and innovations in Six Sigma methodologies for optimizing operations.

- One emerging trend is the integration of digital technologies such as artificial intelligence and machine learning into Six Sigma processes to enhance data analysis and decision-making.

- The use of real-time monitoring systems and predictive analytics is another innovation that is gaining traction in pharmaceutical operations, allowing companies to identify and address issues proactively.

- Continuous improvement through the implementation of lean Six Sigma principles is also becoming more common in the industry, focusing on eliminating waste and improving efficiency in processes.

- Personalized medicine is a growing area where Six Sigma can play a crucial role in tailoring pharmaceutical operations to meet the specific needs of individual patients, improving both outcomes and patient satisfaction.

- Collaborations between pharmaceutical companies and academia to develop new Six Sigma tools and methodologies are on the rise, leading to a more robust and innovative approach to quality management in the industry.